Get 10% off and be the first

to discover new brands!

BioLite

- HEADQUARTERS LOCATION: New York City, USA

- STORAGE LOCATION: Asia, Africa, Europe, North America

MANUFACTURING

- Local Resourcing

- Recycled Materials

- Sustainable & Organics Resourcing

- Local Manufacturing

- Animals Welfare

- Avoiding Chemicals &PFC's

- Green Packaging

EMISSIONS

- Compensating CO2

- Supply Chain & Manufacturing

- Transport Optimisation

ENERGY & WASTE

- Reduction of Water Pollution

- Green Energy

- Waste Management

FAIR LABOR

- Fair Labor & Compensations

- Diversity & Equity

- Health & Safety

- Good Practices & Environment

GIVING BACK

- Ecological & Sustainable Innovation

- Repairing, Recycling & Upcycling

- Circular Design

- Social & Environmental Initiatives

- Partnership with Organizations

TRANSPARENCY

- CSR Report

- Data Sharing & Evaluation

- Spreading knowledge

HISTORY & PHILOSOPHY

Energy sits at the center of our lives, keeping us safe, productive, and comfortable. Energy improves health, combats climate change, enables communication and education, generates income, and empowers women. Creating access for a growing world population has become one of the biggest opportunities of our time.

BioLite is on a mission to bring Energy Everywhere™ with revolutionary products that transform the way we Cook, Charge and Light our lives off the grid. We are a team of engineers and designers, operators and analysts, story tellers and evangelists, who believe that advanced technologies, built on sustainable business practices, have the power to change the world. Our unique Parallel Innovation business model pairs the needs of families living in energy poverty with the passions of outdoor enthusiasts pushing the boundaries of life outdoors and on the go.

Our founders, Jonathan and Alec, met at Smart Design in New York City where they quickly bonded over their interest in sustainable design. Alec, frustrated that almost all efficient camping stoves required fossil fuels, had the idea of a wood-burning stove able to utilize its own thermal energy to improve combustion. Jonathan, an avid camper, quickly brought his engineering background to the table and the two began the design process. Countless nights, weekends, and prototypes later, the BioLite CampStove was born: a portable biomass stove that leveraged thermoelectrics to create a smokeless fire all while charging personal devices.

PRODUCTS

Mobile Energy, Clean Cooking, Efficient Charging.

MANUFACTURING

Through an ethically sourced supply chain, BioLite leverages centralized manufacturing to produce high-quality products at an affordable price.

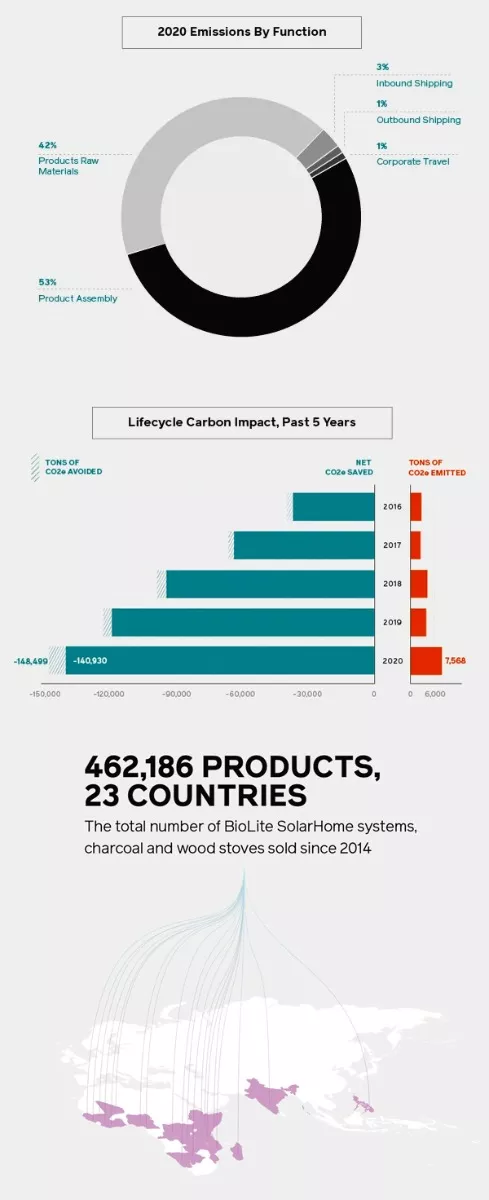

We at BioLite seek to minimize our resource consumption and create products that have a net benefit to humanity and to the planet. Monitoring our carbon footprint is the first step in understanding whether we are achieving this goal. To that end, we have been measuring our carbon footprint since 2012 and offset our entire footprint each year. This process has been particularly important recently since BioLite has been experiencing significant growth, which we aim to achieve in both a financially and environmentally sustainable way.

EMISSIONS

Our process production generate very small amounts of CO2 as we just use a washing machine, scissors and sewing machines. About logistics, we don't measure our CO2 impact, however but we always try as much as possible to reduce distances between our production and our final clients.

We always send our products in bulk from our workshop in Portugal to our wharehouse in France and only by truck, of course we never use plane for the transportation of our bags. Products that are made in France are made less than 30 km away from the wharehouse.

Concerning our trajects as founders, we try to reduce them as much as we can and use the train. As also based in Lisbon, we deal with all the portuguese production. Our associates in the North of France are dealing with the french productions. It allows to stay close to the workshops while reducing distances.

ENERGY & WASTE

About the energy use, in France we rely mainly on nuclear energy so our workshops are not generating any CO2 for the production.

In Portugal, 56% of the energy production is based on renewables.

All the materials we receive are already wastes. Despite that we try as much as we can to revalorise every piece of materials that we can. Leftovers are used to create trousers or laptop bags. We also store the parts we don't use for future needs or we also give them to other companies that are doing upcycling.

We systematically repair all the bags that have issues. For this reason, since we were created we never generated any waste with bags (except if our clients throw them without telling us). We are working to implement a cradle to cradle strategy, by allowing our products to extend their life time. ex: a backpack can be cut to become a toiletry bag.

FAIR LABOR

We work with workshops in the north of france that are hiring disabled employees and people in reinsertion, thanks to that we are trying to offer new opportunities to those two populations that are highly touched by unemployment.

Our portuguese partner is a family workshop that follows all the european regulations and treat their employees with respect. We can verify that every two months when we go there for an inspection.

Finally we try to valorize as much as possible our stakeholders, partners and all the massive crew that is helping La Virgule to show it is possible to produce ethically and locally.

GIVING BACK

We repair all the products that are having issues. We already are a 100% upcycling company.

We try to create the most refined and simple design that we can on our products, to make it is easier to dismantle after its second life.

We ban accessories such as magnets that are hard to recycle. And we try as much as possible to reduce zippers (the only part of our bags that are not upcycled).

We also work with brands (ex: Decathlon) to show them how to design differently their equipments to make is easier to upcycle (ex: not put a buckle in the side of an inflatable kayak to make it easier to dismantle).

We are three founders passionate about sport and outdoors. The company was founded to answer the problem of wastes in the outdoor industry where very qualitative materials were ending in the landfill.

The company was funded with our money and crowdfunding, it is growing organically since then. We don't have any investors that could prevent us to reach our primary objective: to make the world of outdoors circular.

TRANSPARENCY

We share as much as possible the number of equipment that we upcycled for example. You can find this information on our social medias.

Check here BioLite shipping & returns info.

Materials

- Wood